The Galvanized Hexagonal Gabion Box: Unmatched Durability and Versatility

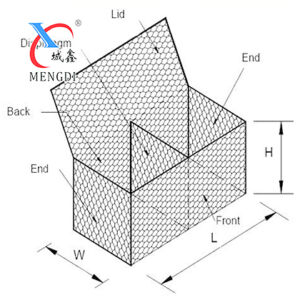

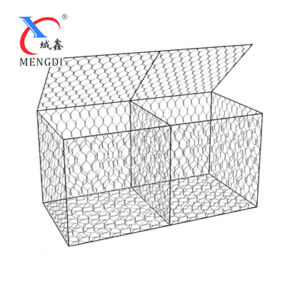

The Galvanized Hexagonal Gabion Box is a revolutionary solution for various construction and landscaping projects. With its galvanized coating, this box offers unparalleled durability, ensuring long-lasting performance even in harsh weather conditions. The unique hexagonal design provides exceptional stability and strength, making it ideal for retaining walls, erosion control, and even decorative purposes. Its versatility allows it to be easily filled with stones, rocks, or other materials, creating a visually appealing and functional structure. Choose the Galvanized Hexagonal Gabion Box for a reliable and cost-effective solution that will exceed your expectations.

Superiority of Galvanized Hexagonal Gabion Box

Our company specializes in the production and export of Galvanized Hexagonal Gabion Boxes. With the help of our exclusive engineers and technicians, high technical production machines, and strict quality control, we ensure that every Galvanized Hexagonal Gabion Box we produce meets the highest standards. Our Galvanized Hexagonal Gabion Boxes have gained a good reputation among worldwide customers for their durability, strength, and corrosion resistance. We are committed to continuously investing in equipment and technology to provide our friends with even better quality products, more competitive prices, and more considerable service.

Galvanized Hexagonal Gabion Box Product Features

The is a high-quality and durable product designed for various applications.

It is made from high grade Low Carbon steel iron wire, heavy zinc coated wire, PVC coated wire though twisting and braiding by machine. as well as galfan coated units. Galfan is a high performance galvanising process using a zinc/aluminium/mischmetal alloy coating. This offers significantly greater protection than traditional zinc galvanizing. Where the product is exposed to water courses or a saline environment, we strongly recommends a polymer coated galvanized unit for improved design life.

Galvanized Hexagonal Gabion Box Product Functions

The serves multiple functions, making it a versatile choice for different projects. Some of its main functions are:

Galvanized Hexagonal Gabion Box Product Advantages

Choosing the comes with numerous advantages.

The product uses a high-performance galvanizing process of zinc/aluminum/mixed rare earth alloy coating, which provides greater protection than traditional galvanizing. If the product is exposed to waterways or saline environments, we strongly recommend using polymer coated galvanized devices to extend the design life.

Galvanized Hexagonal Gabion Box Performance and Parameters

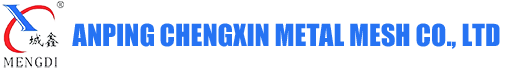

The is built to deliver exceptional performance. Its key performance and parameter details are as follows:

| Aperture | 6cm*8cm, 8cm*10cm, 10cm*12cm, 12cm*15cm |

| Mesh Wire Diameter(SWG) | 8- 12 -14 Gauge |

| Selvedge Wire(SWG) | 8- 11 -13 Gauge |

| Lacing Wire(SWG) | Commonly 13 Gauge |

| Color | Darkgreen, gray, black, etc. |

| Material | Galvanized wire, galfan wire and PVC coated wire |

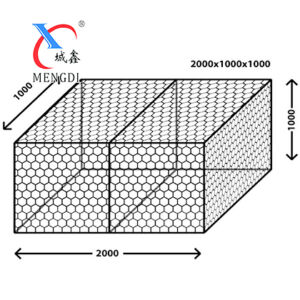

| Common Size | 2m*1m*1m, 3m*1m*1m, 4m*1m*1m, 2m*1m*0.5m, 4m*1m*0.5m, |

| Weight | 1.57kg/㎡ |

| Packing | 1. Compacted before packaging. 2. Plastic packaging outside and on the pallet. 3. 20’container can contain more than 8,000 square meters. 4. 40′ container can contain more than 15,000 square meters |

| Feature | Strong structure and corrosion-resistance to protect the dam and riverbank |

| Application | Control and guide of water or flood、Preventing of rock breaking、Rock fall protection、Water and soil protection、Bridge prot |

Galvanized Hexagonal Gabion Box Product Applications

The finds extensive use in various applications. Some common areas where it can be applied are:

Galvanized Hexagonal Gabion Box Product Usage

Using the is straightforward and hassle-free. Here’s a step-by-step guide on how to use it effectively:

Galvanized Hexagonal Gabion Box Product Selection

Choosing the right is essential for optimum results. Consider the following factors when selecting the product:

Packing & Delivery

1. Compacted before packaging.

2. Plastic packaging outside and on the pallet.

3. 20’container can contain more than 8,000 square meters.

4. 40′ container can contain more than 15,000 square meters.

Installation Instructions